MTS Turbo-Screen Filters

Contact to order

Please reference part # MTS-3NA when

you get in touch. Thank you!

More Information

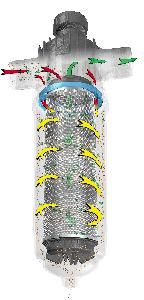

THE BODY The body contains one inlet and two outlets, allowing the filter to be installed at either 90 or 180-degrees. A threaded cap is supplied with the filter to terminate the outlet port not being used. Inlet/outlet connections are available in NPT or Victaulic. The body contains inlet and outlet pressure gauge ports (gauges not included). The gauges monitor the pressure differential across the filter screen which determines when the screen cartridge needs to be removed for maintenance.THE CLOSURE Manufactured in Type 316 stainless steel, the quick-release clamp assembly is strong and reliable. No tools are necessary to remove the clamp and filter cover when maintenance is required.

THE SCREEN Screen options offer a variety of stainless steel screen sizes, from coarse perforated material to a fine mesh. The two-dimensional screen filter is ideally suited for removal of hard, non-organic particles such as sand. Standard screen material is Type 316 (see screen sizes available below).

THE LID

�The lid is injection-molded, using an incredibly strong polyamide material. The centrifugal action, created by the Helix-Element, spirals heavier particles down to the base of the filter. The particles are then flushed, either manually or automatically, from the 3/4" flush port at the lowest point in the lid.

�The lid is injection-molded, using an incredibly strong polyamide material. The centrifugal action, created by the Helix-Element, spirals heavier particles down to the base of the filter. The particles are then flushed, either manually or automatically, from the 3/4" flush port at the lowest point in the lid. UNIQUE FEATURES

- Centrifugal cleaning action minimizes maintenance

- Large screen surface area with maximum open area

- Particles can be flushed while filter is in operation

- Several Type 316 stainless steel mesh (and perforated) options available

- Durable, corrosion-resistant, injection-molded housing

- Easily removable, quick clamp lid assembly

- Pressure gauge ports molded into housing

- Mounting Bracket (sold separetly)

- Dirty Water Enters the Filter Housing Through the Inlet Connection.

- As Dirty Water Passes Through the Helix-Element, the Water Starts to Spin at High Velocity. This Centrifugal Action Spins the Particles Away From the Screen, Minimizing Manual Cleaning Frequency.

- As Particles Are Spun Down to the Base of the Filter, They are Flushed Via the 3/4" Female Threaded Flush Port Connection.

- The Dirty Water Passes From the Outside to the Inside of the Stainless Steel Screen. The Screen Captures the Remaining Light and Fibrous Contaminants in the Water.

- After Passing Through the Screen, the Filtered Water Flows Upward and Exits the Filter Through One of the Outlets. The Outlet Not Being Used is Terminated With a Threaded Cap.

TECHNICAL DATA

Flow Rates and Pressure Loss for a Single Filter Housing- 2"/100 GPM Max.* @ 3.5 PSI Loss

- 2" Super/100 GPM Max.* @ 3 PSI Loss

- 3"/200 GPM Max.* @ 5 PSI Loss

high solids loading, particularly for finer

mesh sizes.

Pressure Rating

- All Units Rated to 125 PSI

- All Units Rated to 140� F

- 2" and 3" Models Available With NPT and/or

Victaulic Inlet/Outlet Connections - In-line and 90 degree configurations standard

Construction Materials

- Housing: Polyamide

- Screen: Stainless Steel (Type 316)

- Gaskets: EPDM

- Filter Pod Clamp: Stainless Steel (Type 316)

- MESH OPTIONS:

16, 30, 40, 50, 60, 80, 100, 120, 150, 200 - PERF OPTIONS:

1/4" Perforated, 1/8" Perforated, 1/16" Perforated

Helix MTS Quick Reference Chart

| Model Number | Model Type | Inlet/Outlet Size & Type | Filter Surface Area (sq. in.) | Flush Port Connection Size | Max Flow (GPM) | Max Pressure Rating (PSI) |

|---|---|---|---|---|---|---|

| MTS-2NA-* | Regular | 2"/NPT | 186 | 3/4" | 100-GPM | 125-PSI |

| MTS-2SA-* | Super | 2"/NPT | 263 | 3/4" | 100-GPM | 125-PSI |

| MTS-3NA-* | Regular | 3"/NPT | 263 | 3/4" | 200-GPM | 125-PSI |

| MTS-2NW-* | Regular | 2"/Victaulic | 186 | 3/4" | 100-GPM | 125-PSI |

| MTS-2SW-* | Super | 2"/Victaulic | 263 | 3/4" | 100-GPM | 125-PSI |

| MTS-3NW-* | Regular | 3"/Victaulic | 263 | 3/4" | 200-GPM | 125-PSI |

*Please specify size when ordering. Example: MTS-2NA-100 = 2" NPT Regular Filter with 100 - mesh screen. Screen cartridges for 2" regular models (MTS-2NA and MTS-2NW) and 2" Super models (MTS-2SA and MTS-2SW) vary in size. The cartridge for the 2" regular models is 15.5" in height. The cartridge for the 2" super models is 20.5" in height. This means that the 2" super models have approximately 40% more surface area for filtration (186 sq. inches vs. 263 sq. inches).